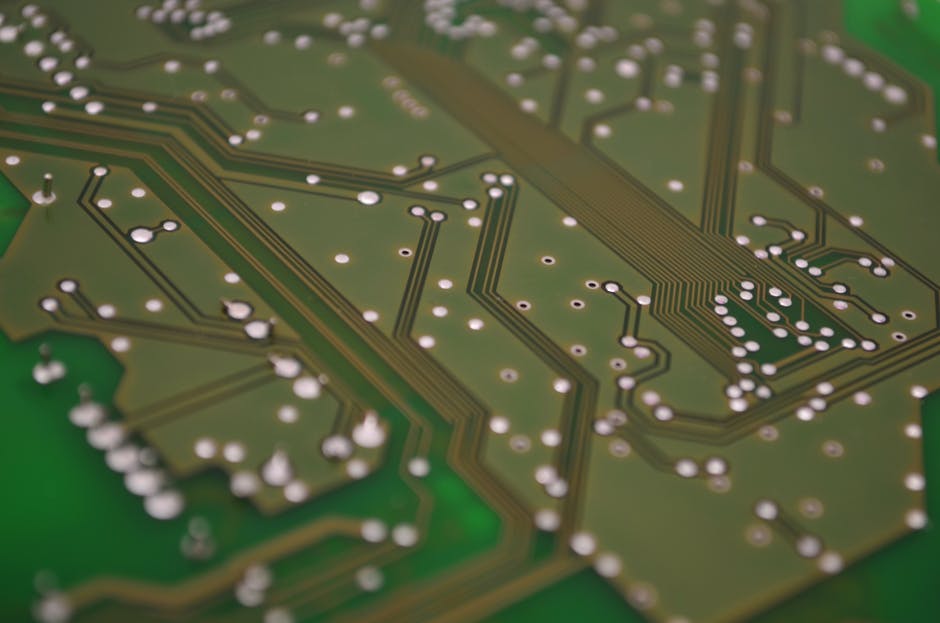

Electrical components are connected to printed circuit boards, which allow voltage to be routed and components to be routed. A PCB is a thin board made from fiberglass, epoxy or another laminate material. Most electronic equipment uses PCBs, from computer systems to radios and radars. Each Best PCB manufacturer is designed to serve a particular function. Connecting the electronic components is made easier by the PCB’s traces. Circuit boards are connected by soldering components onto them.

PCBs come in several types:

Let’s begin by discussing the major types of printed circuit boards. Several factors determine the structure, including the number of layers and the metal used. PCBs can be categorized into three different categories.

PCBs with one side:

Among all PCBS, this is the most basic. A copper or any metal layer is deposited on one layer of a substrate. PCB dielectric bases have conductors only on one surface. Typical applications include sensors and electronic toys.

PCBs with double sides:

Both sides of a double-sided PCB are covered with a metal layer. In the board, holes are drilled for attaching parts as well as connecting the plates. Mobile phones, amplifiers, and other devices utilize these PCB types.

PCBs with multilayers:

Multilayer PCBs consist of more than two layers of copper. In between the copper layers are many insulating layers. PTH (plated through holes) interconnect these layers.

You can request a quote online at PCBGOGO if you are interested in any of the above services. Electronicslovers published a product review of PCBGOGO -> Best PCB Manufacturing Company in China – PCBGOGO Review

Boards made of printed circuits have the following advantages:

Other alternatives like breadboards and point-to-point construction are also available, but PCBs are the most commonly used. There are many advantages to using them over other options, and so they are preferred. The following are some of them.

1: Compact size and reduced wire usage

There are many components that can be mounted on PCBs. Components of this size may be too small to be connected by wiring, as their sizes may be very small. In addition to connecting all these components, PCBs allow copper tracks to be used instead of wires, which makes it much easier to hold small components and saves wires. Furthermore, a small circuit board can accommodate many components, making it compact. Thus, complex and large circuit designs can be reduced in size by using a compact form factor.

2: It is easily repairable:

If your PCB is malfunctioning, you can easily repair it. The reason for this is that the polarity of the components is silk screened onto the board, which is very convenient for checking and repairing. In addition to convenience in the building process, repair is also facilitated.

Save time by:

It takes a long time to make circuit boards conventionally. Printed circuit boards take less time and are more convenient than other methods.

Components 4 and 5 are fixed:

Circuit boards are built by soldering all the components on and fixing them into place. As a result of solder flux, components are not allowed to move.

Short circuits are less likely:

Copper tracks or conductors are used to make all the connections. The chances of a short-circuit occurring on the board are therefore reduced.

The use of electronic devices should be kept to a minimum:

In order to minimize electronic noise, the PCBs are constructed so that it is barely detectable. All noise is dispersed as heat or radiation. No noise comes from a properly laid out PCB. Because the components are arranged so that there are very few path lengths, there is less radiation and EM waves generated.

More Stories

Choosing the Right Business Loan For Your Company

How Twitter Can Help Your Business

Facebook Small Business Marketing – How To Get More Traction