3D printing offers many advantages, are you aware? Learn the top ten advantages of 3D printing here.

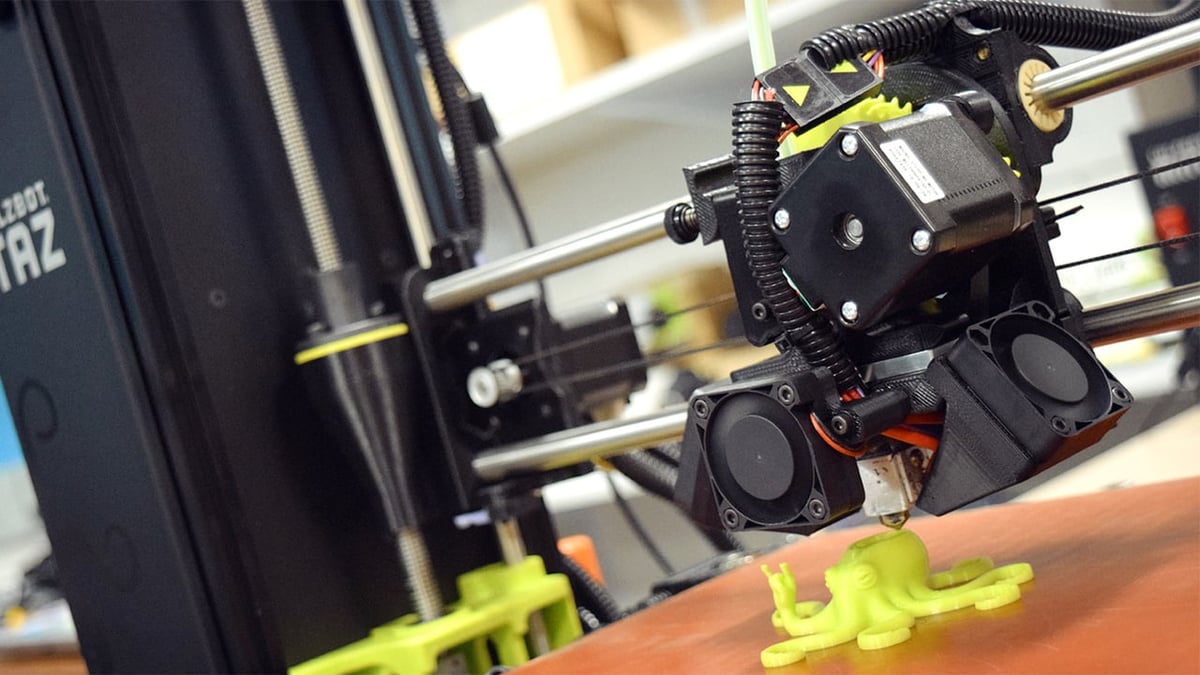

The product development process consists of 3 main steps, namely from the idea to the physical, 3-dimensional prototype of the product.

The process of subtractive manufacturing involves continuously cutting away material from a solid block, such as metal. Alternatively, CNC (Computer Numeric Controlled) machines can be used.

1. ACCELERATED

Rapid prototyping is one of the biggest benefits of 3D printer Price technology. In rapid prototyping, parts are designed, manufactured, and tested in a short period of time. It is also possible to modify the design if needed without affecting the manufacturing process.

A prototype used to take weeks to build before the 3D printing industry took off. With each change, the process took a few weeks longer. Considering shipping times, it could easily take an entire year to develop a product from start to finish.

In just a few days (and sometimes even less), a business can design and manufacture a part on a professional 3D printer and test it.

2. PRICES

Three-dimensional printing is the most cost-effective manufacturing process for small production runs and applications. CNC machining and injection molding are traditional prototyping methods that require high machine costs and labor costs as they require machine operators and technicians with experience to operate them.

3. AFFLEXIBILITY

Almost anything can be created with 3D printing, as long as it fits within the build volume of the printer.To create a new part with traditional manufacturing processes, a new tool, mould, die, or jig has to be manufactured.In 3D printing, the design is sent to a slicer, the needed supports are added, and then the object is printed without any changes in the physical machinery or equipment.

4. COMPETITION ADVANTAGE

Three-dimensional printing reduces product life cycles because of its speed and low cost. By improving and enhancing a product, companies can deliver better products in less time.

5. TESTING AND DESIGN OF TANGIBLE PRODUCTS

Seeing a prototype on a screen cannot compare to touching and feeling it, as previously described in competitive advantages. If flaws are found in the prototype, the CAD file can be modified, and a new version can be printed out the next day.

6. SATISFACTION

Poor designs can lead to poor quality prototypes when using traditional manufacturing methods. As an example, let’s imagine baking a cake, where all of the ingredients are combined, mixed, and baked. As a result of not mixing well, there would be air bubbles in the cake or the cake would not bake properly. Adding or subtracting may have the same result; quality isn’t always guaranteed.

7. COMPLETENESS

In terms of quality, traditional manufacturing processes can cause a percentage of parts in a batch to be defective or inconsistent compared to the rest of the batch.A 3D printer prints parts sequentially. By monitoring each successive part in real time, errors can be caught immediately, reducing overall failures and waste materials, while increasing consistency in quality.

8. REDUCING RISKS

Using 3D printing, a business is able to mitigate manufacturing risks due to its advantages of Quality and Consistency. Using 3D printing technology, product designers can verify prototypes before making substantial investments in manufacturing that can be disastrous.

9. ACCESSIBLE

Traditional manufacturing setups are inaccessible to a much broader range of people than 3D printing. Setup of a 3D printing setup is considerably cheaper than traditional manufacturing systems. The process is also much more accessible than other manufacturing systems due to the fact that 3D printing is almost completely automated and requires very little additional staff to run, oversee, and maintain the machine.

10. SUSTAINABILITY

The manufacturing of 3D printed parts requires less outsourcing. As a result, less is shipped around the world and fewer factories need to be operated and maintained.

More Stories

Choosing the Right Business Loan For Your Company

How Twitter Can Help Your Business

Facebook Small Business Marketing – How To Get More Traction